Perhaps it’s the colder weather or perhaps the glass fibers I’ve inhaled are tickling my hypothalamus, but today I woke up early with the minimum of suicidal thoughts and have gotten a lot of stuff done. And it’s not even noon!

Most importantly, I’ve gotten around to ordering all the electronic component and connectors needed to finish the Gen7 1.2 motherboard and optostops. When envisioning the project, I was determined to bond with ELFA, to find a weary comrade at the store who would regale me with tales of how she set fires on things in her first project as well, and I would offhandedly follow the advice and recommendations for what to buy. Then I realised that ELFA is up to three times as expensive as some of the net stores, so screw that.

Last night I was up with a bottle of wine and a Dremel, trying to drill really fucking teensy holes in the PCBs. I was wearing a mask most of the time, but some of the glass fiber is bound to end up in my brain. Considering I’m doing this in the kitchen, let’s call it additional roughage. The drilling went well, and I managed to substitute the smallest drill bit with the conical diamond bit. I thought I would need a press drill for precision, seeing as the smallest holes are half a millimeter or so, but as long as you limit yourself to two glasses of wine you’re good. At three glasses you become a bit cavalier re:precision.

The parts I ordered were mostly from Reichelt with some remaining stuff from RS Components. Reichelt has a nice webstore with pretty pictures and all, but their customer service is either shy or enjoys receiving multiple emails with similar questions. Most businessess, I imagine, upon receiving an email asking “can I pay with Mastercard or do I pay on delivery?” would answer both parts of the sentence, not limiting themselves to “You cannot pay with Mastercard.” Playing coy might be a good way of wooing the shy guy with a beret, but I’m trying to pay for your services so no need to beat around the bush here.

Before I got to the stage of drilling holes and ordering parts, let me tell you the story of how I learned of which parts to order. I believe it’s telling of how quickly one gets mired in tracking down information when you know as little as I do on a topic.

In order to make the PCB I had to find a list of the required parts to mount on the PCB. I couldn’t find anyone who could tell me what parts are required. I couldn’t find a written list of parts, but there were instructions somewhere on the wiki telling me to open up a file of a certain type, changing a setting in an application, and then export a BOM — Bill Of Materials. No hint of what the file name is nor what application is required, but OK.

So I go onto the #reprap IRC channel and ask my stupid questions and get very little response. Someone recommends that I check out gEDA PCB, an open source application for creating PCBs and schematics, because EAGLE might not be able to open the file I need to open, whichever file that is. GEDA is actually mentioned on the wiki, but there’s no information as to what it is or where to get it, so I thought it was a filetype at first.

I check out gEDAs homepage, which tells me that I need to compile the application from source. Ok, so poke about a bit then realise that gEDA requires FINK to install, which in turn requires installing FINK and dependencies via the Terminal, which I’m shamefaced to admit I suck at using. FINK requires the Xcode developer tools, so I leave that to download for half an hour and then have the Devtools install running in the background while I try to get a feel for the RepRap IRC community.

Among the running chatter of people troubleshooting their machines, there was some discussion about the first case of 3D fabbing copyright infringement, when someone recreated a prop from a Paramount movie and they got on his case. It’s surely a sign of things to come, but as long as there are open source 3D apps and DIY printers, I don’t see how you could stem the tide of personal infringement. It’s a short read and worth checking out:

→ Torrentfreak, enigmax: Paramount Cease and Desist Targets 3D Printer ‘Pirate’

Anyway, with the Xcode developer tools installed, I notice that FINK isn’t available as a binary for 10.6, so I download a tarball and follow the instructions for compiling FINK using the Bash Terminal. Compiling FINK has actually been the most straightforward thing I’ve done so far, as the installation was really friendly and considerate; Like a well lubed proctologist with good blood circulation.

It took me a moment to realise that I need to enable unstable packages in FINK, after which gEDA installed fine while I fell back on default selections when asked about plugins and whatnot. I’m not sure if I screwed something up in the process, cause gEDA took two hours to compile even though I had engaged all eight cores.

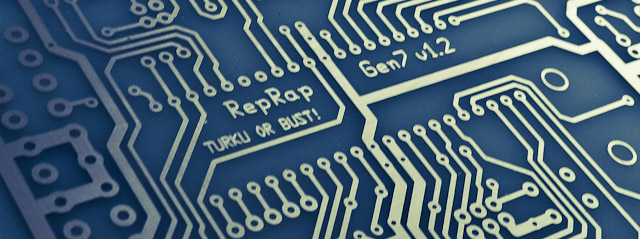

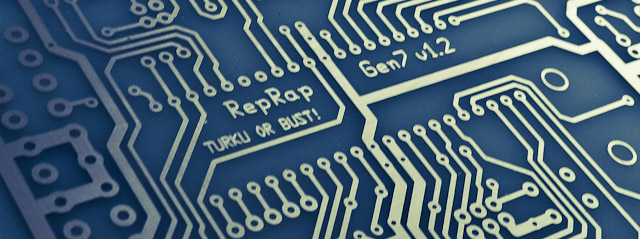

With gEDA installed, I find the PCB app in ~/sw/bin/pcb and open up the Gen7Board.pcb file from the app. And lo and behold, there’s a “BOM” alternative under “Export…” which gives me a list of components and their place on the board. All in a text-file which you have to manually open cause it has no filetype extension. Looking over the list of parts, I’m still confused since some of the parts are labelled “unknown” which is somewhat ominous. In the chat, Traumflag himself shows up (The guy who created and maintains Gen7 1.2) and I ask my silly questions again.

Turns out, there’s a complete parts list on the wiki, and he promptly sends me a link.

Now. When you’re as green as I am on a subject, it can be difficult for an outside observer to distinguish me from a lazy bum, but I swear I’ve gone up and down that fucking wiki and not found any links to a parts list for the Gen7 1.2 board. Apparently, Google can’t find any pages linking to it either (as of July 1st at least) so perhaps there aren’t any. I don’t know how it’s possible not to link internally somewhere on a wiki, but at least it made me feel less stupid, albeit still frustrated.

In grassroots open source project such as the RepRap community, writing documentation is boring and little value seems attributed to it and consequently little work is done on it; On the other hand, it’s really simple to get in touch with whomever designed the part you need help with, and people are often kind and willing to lend a hand.

So, with a followup email from Traumflag, I had a complete list of parts. And since the wiki contained direct store links to the components, I took the sensible approach and ordered the goddamn parts already. Though Reichelt slapped on some banking fee, the parts were most certainly cheaper than ELFA; And even if I could have tried to source cheaper components, that would have taken me a couple more days, which I rather spend solving the next problem down the road. Which I predict there will be aplenty.